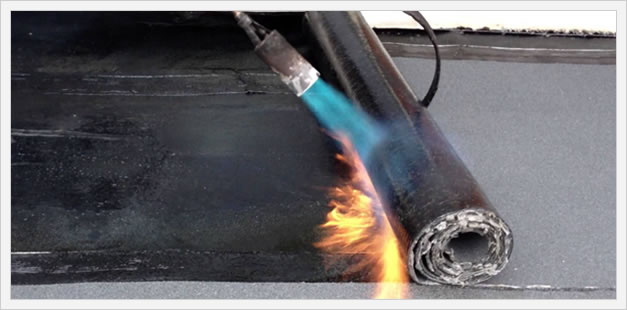

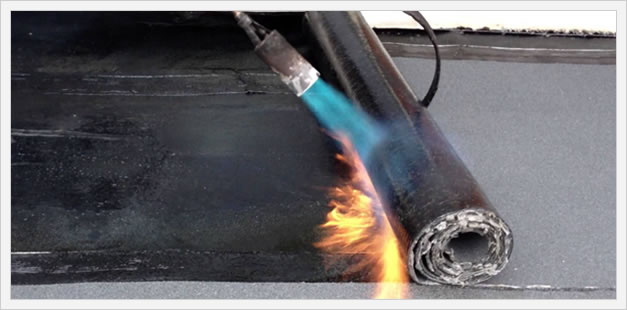

Torch down roof application.

Torch down modified bitumen rubber roofing.

While it can last up to 20 years installing torch down roofing can be a dangerous process and as such tends to cost more than traditional roofing materials.

See the steps to take on flat roof repairs for a torch down rubber membrane.

This roof is located on 819 westport rd east westport connecticut.

The membrane is available with a smooth surface.

This roof is located on 819 westport rd east westport connecticut.

As long as it is installed correctly bitumen prevents moisture build up without needing constant maintenance.

In the late 1970 s and first manufactured in the u s.

The mat is coated with durable app modified bitumen and is designed for torch down application by professional roofing contractors.

Smooth surface can be used as a cap or interplay membrane ideal for new roofs and repairs of built up or sbs modified bitumen systems meets astm d6222 type i grade g.

Both epdm and modified bitumen torch down rubber membranes were making their way into the roofing industry early on.

The membrane layers of a torch down roof are made of an asphalt compound called bitumen that is modified with either rubber or plastic.

Ruberoid torch smooth membrane is backed by gaf a company with over 130 years in the roofing business.

Torch down roofing is a type of roofing material that has been designed for low angle or flat roofs.

Apply the bitumen by melting it over fiberglass mesh with a propane torch.

Sbs is a type of rubber used to create modified bitumen for torch down roofing.

Modified bitumen torch down rubber roofs are heat welded at the seams.

Torch down roofing with modified bitumen modified bitumen mb torch down roofing membranes were first developed in europe in the mid 1960 s introduced in the u s.

Its core is a strong resilient non woven polyester mat that is coated with weather resistant app polymer modified asphalt.

Coated modified bitumen rubber roof.

Rubber roofs were introduced in the late 60s in the united states.

Torch down roofing consists of modified bitumen which is similar to asphalt.

This means that sbs membranes can be used in torch down roofing as well as self adhering and cold processed roofing systems.

The modified bitumen torch down roof below was installed by us over 14 years ago.

Just look at the age of the roofs and notice what type of repairs have been done.

The membrane is composed of various types of modifiers reinforcements and surface treatments.

Sbs modified bitumen membranes are also flexible and they have a lower melting point than app membranes.

The main strength of this type of roofing is that it can expand and contract without melting or cracking.