Improving production material efficiency to 70 would reduce the embodied emissions and material costs of the sheet metal car structure by 26 and 24 respectively.

Yield improvement in sheet metal.

Energy used in industrial activity produces 40 of global co2 emissions the majority of which are.

Improving production material efficiency to 70 would.

Yield strength and yield improvement of the product are done by simulating stress analysis by using catia software.

Tensile yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart.

The objective of this paper is.

Yield strength tensile strength and ductility values for steels at room temperature.

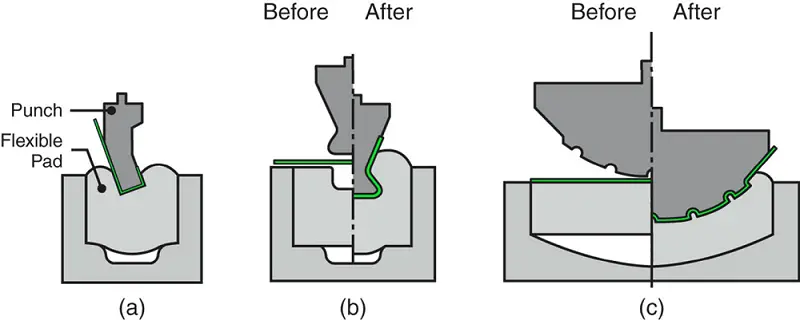

Using filler parts to manage sheet yield and reduce remnants.

Filler parts are parts with a less than urgent priority.

Through an industry study this paper estimates that yield losses account for 44 of sheet metal used in the production of passenger vehicles.

There are three strategies commonly used to manage filler parts.

They are parts that can be made now but are made from scrap or material that would be a remnant.

Yield improvement opportunities for manufacturing automotive sheet metal components 1.

Through an industry study this paper estimates that yield losses account for 44 of sheet metal used in the production of passenger vehicles.

This could provide a global annual saving opportunity of 25 million tonnes of co 2 and 8 billion.